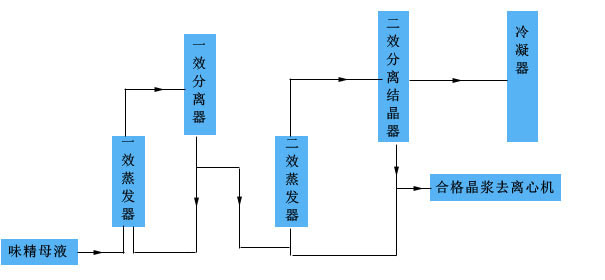

Aginomoto nruam crystallization txheej txheem

Txheej txheem cej luam

Nws muab cov cuab yeej thiab txoj hauv kev rau kev tsim ntawm lub substrate crystalline semiconductor txheej.

Cov txheej semiconductor yog tsim los ntawm vapor deposition. Executive pulsed laser melting / recrystallization txheej txheem rau semiconductor txheej rau hauv crystalline txheej. Lub laser los yog lwm yam pulsed electromagnetic tawg tawg thiab yog tsim raws li ib tug uniformly faib nyob rau hauv cov kev kho mob cheeb tsam, thiab tsis tu ncua raug mus rau qhov chaw ua hauj lwm nyob ib ncig ntawm lub burst hais tias, mus rau progressively deposited cov ntaub ntawv yog hloov dua siab tshiab rau cov khoom siv crystalline.Nruam noj thiab tawm, thiab cov concentration, kub, crystal slurry ntom thiab siv lead ua loj faib ntawm tag nrho cov kua nyob twj ywm unchanged thaum lub sij hawm crystallization txheej txheem.

1. Txhawm rau hloov mus rau cov qauv kev tsim khoom tas mus li, cov txheej txheem kev tsim khoom tas mus li kev tswj xyuas qhov tseeb yog siab dua, cov zis ntau dua, kev tsim khoom ruaj khov, thiab nws yooj yim rau kev sib txuas nrog lwm cov txheej txheem, uas yog ib qho ntawm cov qauv kev lag luam kev lag luam yav tom ntej.

2. Lub crystallization yield tuaj yeem txhim kho tau zoo, thiab cov khoom lag luam poob hauv niam cawv tuaj yeem rov qab los ntawm ntau theem countercurrent txoj kev, thaum ua tau raws li kev cai lij choj, thiab txo qis kev tsim cov khoom siv pov tseg pov tseg.

3. Lub purity ntawm cov khoom tuaj yeem txhim kho tau zoo, thiab kev sib cais ntawm cov khoom tseem ceeb thiab cov impurities tuaj yeem nthuav dav los ntawm ntau theem countercurrent txoj kev, yog li cov ntsiab lus ntawm cov khoom tseem ceeb tuaj yeem nce ntxiv, thiab qhov zoo ntawm cov khoom kawg tuaj yeem txhim kho.

4.Minimize qhov sib txawv ntawm batch. Kev tswj tsis siv neeg tag nrho thiab kev saib xyuas hauv online tuaj yeem siv los txo qhov sib txawv los ntawm kev ua haujlwm ntawm phau ntawv thiab qhov tsis ruaj khov los ntawm cov kauj ruam ua ntej.

Nyob rau hauv qab daus ntawm MSG ib qho kev cuam tshuam crystallization lauj kaub, cov cuab yeej siv cov txheej txheem ntawm ob qhov cuam tshuam, nce zaj duab xis, decompression evaporation, cov chav tshiab muab cov cua sov rau thawj zaug, piv nrog cov txheej txheem qub, cov cuab yeej no txo 50% feem pua ntawm chav noj. Crystallization yog tus kheej tsim Oslo elutriation crystallizer tsis nplawm

Lub cuab yeej txais kev pabcuam tsis siv neeg los tswj.

Thib peb, cov txheej txheem flow chart