Tsib-Kab Peb-Tsev Cov Txheej Txheem Ntau-Pressure Distillation

Txheej txheem cej luam

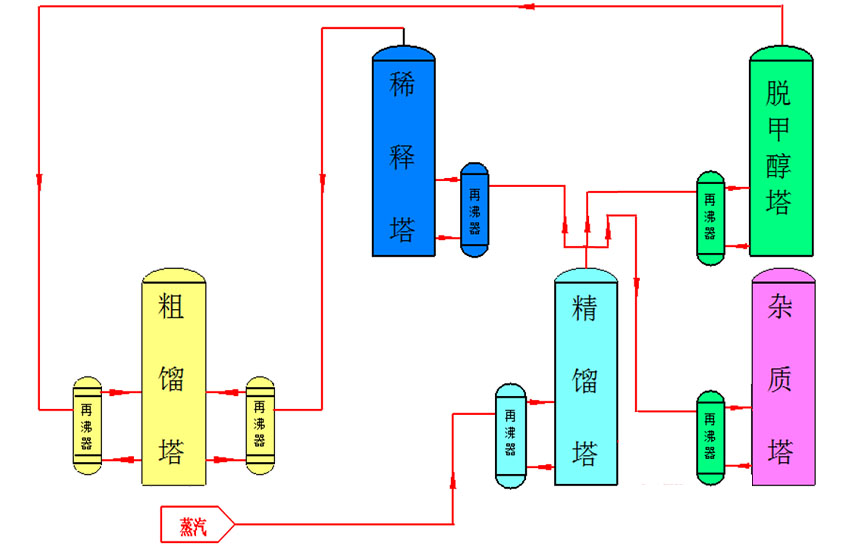

Lub tsib-ntev peb-ntev yog lub zog txuag hluav taws xob tshiab tau qhia los ntawm cov tsoos tsib-ntauwd sib txawv siab distillation, uas feem ntau yog siv rau kev tsim cov cawv qib hwm. Cov cuab yeej tseem ceeb ntawm cov tsoos tsib-ntauwd sib txawv siab distillation suav nrog ntauwd distillation crude, ib tug dilution ntauwd, ib tug rectification pej thuam, methanol ntauwd, thiab ib tug impurity ntauwd. Cov txheej txheem cua sov yog tias lub ntauwd rectification thiab lub dilution ntauwd yog rhuab los ntawm thawj chav los ntawm reboiler, thiab lub rectification ntauwd wine vapor muab cua sov rau crude distillation ntauwd los ntawm lub reboiler. Lub dilution ntauwd wine vapor muab cua sov rau methanol ntauwd los ntawm reboiler. Lub impurity ntauwd siv cov khoom siv hluav taws xob ncaj qha los muab cov cua sov ncaj qha, thiab chav noj yog loj. Cov cuab yeej tseem ceeb ntawm tsib-kem peb-txhim kho qhov sib txawv siab distillation kuj tseem yog lub tshuab hluav taws xob tsis zoo, lub tshuab hluav taws xob dilution, lub ntauwd rectification, methanol ntauwd, thiab ntauwd impurity.

Qhov thib ob, cov yam ntxwv ntawm cov txheej txheem

1. Cov txheej txheem peb-txheej thermal coupling txheej txheem ntawm cua sov lub dilution ntauwd, de-methanol ntauwd, impurity ntauwd, thiab ces diluting ntauwd thiab de-methanol ntauwd kom sov lub crude distillation ntauwd kom txo tau cov pa noj. Kev tsim cov tons ntawm qib zoo cawv haus yog 2.2 tons.

2. Lub degassing seem thiab cov separator yog teem rau sab sauv ntawm crude distillation ntauwd kom txo tau impurities xws li cov khib nyiab uas muaj nyob rau hauv crude cawv nkag mus rau hauv lub rectification system, yog li txhim kho lub purity ntawm crude cawv.

3. Lub crude distillation ntauwd reboiler txais cov cuab yeej siv thev naus laus zis ntawm thermosyphon ncig cua sov es tsis txhob yuam kev cua sov hom, thiab lub zog txuag hluav taws xob yog qhov zoo tshaj plaws, thiab qhov tshwm sim ntawm qhov cuam tshuam ntawm reboiler tshav kub pauv raj yog tshem tawm.

4. Cov khoom ntim tooj liab yog ntxiv rau lub tshuab distillation los txhim kho qhov saj ntawm cov cawv tiav lawm.

Thib peb, cua sov txoj kev

Tus yuam sij rau lub zog txuag ntawm cov txheej txheem no yog nws cov cua sov hom, nyob rau hauv uas cov thawj chav yog dhau los ntawm ib tug reboiler kom sov lub rectification kem. Lub distillation ntauwd wine chav yog nkag mus rau methanol kem thiab lub dilution ntauwd los ntawm ib tug methanol kem reboiler thiab ib tug dilution kem reboiler. Lub dilution ntauwd thiab methanol ntauwd cawv vapor yog feem ntau dhau los ntawm crude distillation kem reboilers A thiab B los muab cov crude distillation ntauwd. Lub distillation ntauwd cov dej khib nyiab flashes ncu kom muab cov impurity ntauwd. Ib tus pej thuam nkag mus rau hauv chav thiab tsib lub yees kom ua tiav peb qhov cuam tshuam thermal coupling kom ua tiav lub hom phiaj txuag hluav taws xob. Kev tsim cov tons ntawm qib zoo cawv haus yog 2.2 tons.

Plaub, cov khoom siv sib txawv

Lub fermented mature mash yog pub los ntawm sab saum toj ntawm crude distillation kem tom qab ob theem ntawm preheating. Cov cawv vapor nyob rau sab saum toj ntawm crude distillation ntauwd yog condensed thiab ces dilute thiab purified rau hauv ib tug dilution ntauwd kom dilute cov cawv crude rau 12-18% (v / v). Cov cawv hauv qab yog preheated thiab tom qab ntawd nkag mus rau hauv cov pej thuam rectification ntawm sab sauv kab ntawm kab distillation. Cov cawv (96% (v/v)) raug coj tawm mus rau sab de-methanol kom tshem tawm cov impurities xws li methanol, thiab cov cawv tiav lawm raug tshem tawm hauv qab.

Lwm qhov zoo

1. Nyob rau hauv cov nqe lus ntawm kev txuag hluav taws xob, lub thermosiphon reboiler lub voj voog cua sov txoj kev hloov cov cua sov cua sov hom, thiab siv peb cov cuab yeej patented kom tsis txhob muaj qhov thaiv ntawm lub reboiler tshav kub exchanger raj. Kev haus cawv ib tuj cawv yog 20kwh. Piv nrog rau kev txhim kho ntawm thawj tsib tus pej thuam sib txawv siab distillation 40-45kwh, lub zog txuag yog 50%, uas zam kev txij nkawm ntawm reboiler yuam kev twj tso kua mis thiab prolongs lub neej kev pab cuam ntawm lub reboiler.

2. Impurity wine kev kho mob: impurity cawv los ntawm crude distillation ntauwd, dilution ntauwd, methanol ntauwd, thiab lwm yam., thiab lub teeb wine los ntawm lub fusel roj separator nkag mus rau hauv impurity ntauwd, thiab muaj dej cawv yog muab rho tawm tom qab lub impurity ntauwd condenser yog tas. Cov roj fusel tau muab rho tawm, thiab cov dej cawv nyoos tawm ntawm kab sab saud yog tom qab ntawd dhau mus rau cov neeg siv ntauwd kom nce qib qib cawv cawv.

3. Nyob rau hauv cov nqe lus ntawm kev txhim kho cov cawv zoo, ntxiv rau cov kev ntsuas thev naus laus zis, cov qauv ntawm cov cuab yeej kuj tau txhim kho. Lub crude distillation ntauwd yog nruab nrog cov khoom siv kua txiv hmab txiv ntoo purification, thiab ntauwd distillation yog muab nrog tooj liab muab tshuaj tua kab mob los xyuas kom meej qhov purity thiab saj ntawm cawv.

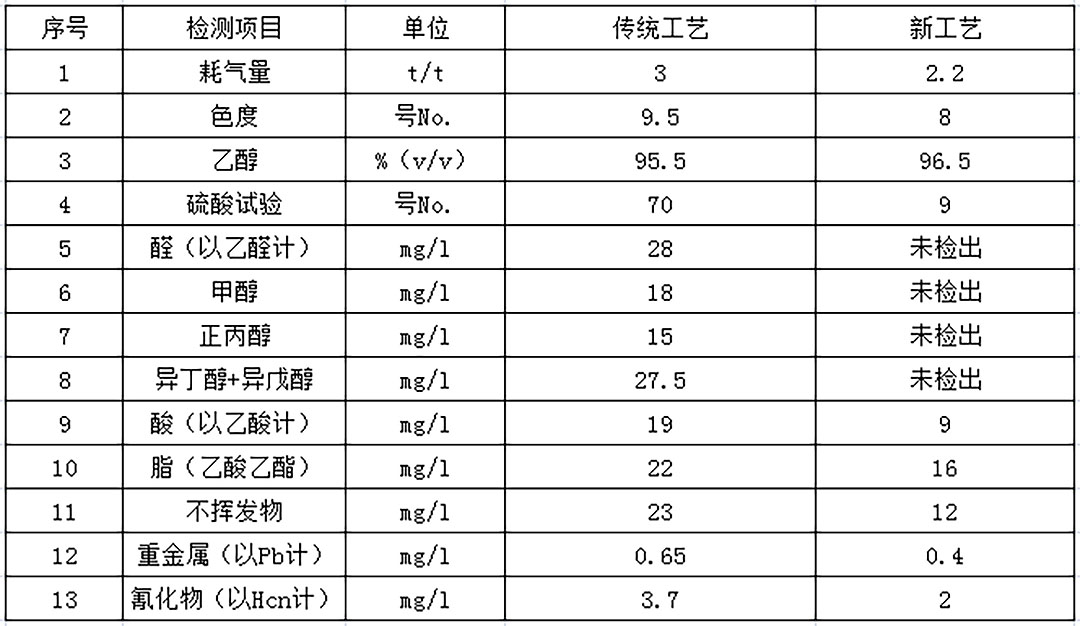

Thib rau, qib zoo cawv cawv siv zog thiab cov lus sib piv zoo.