evaporation thiab crystallization technology

Molasses cawv pov tseg kua tsib-effect evaporation ntaus ntawv

Txheej txheem cej luam

Qhov twg los, yam ntxwv thiab kev puas tsuaj ntawm molasses cawv dej khib nyiab

Molasses cawv dej khib nyiab yog qhov muaj siab thiab muaj xim zoo nkauj cov dej khib nyiab tawm los ntawm cov dej cawv cawv ntawm lub Hoobkas qab zib los tsim cov cawv tom qab fermentation ntawm molasses. Nws yog nplua nuj nyob rau hauv protein thiab lwm yam organic teeb meem, thiab kuj muaj ntau inorganic ntsev xws li Ca thiab Mg thiab ntau dua concentrations. SO2 thiab lwm yam. Feem ntau, pH ntawm cov dej khib nyiab yog 4.0-4.8, COD yog 100,000-130,000 mg / 1, BOD yog 57-67,000 mgSs, 10.8-82.4 mg / 1. Tsis tas li ntawd, feem ntau ntawm cov dej khib nyiab no yog acidic, thiab xim yog siab heev, xim av-dub, feem ntau suav nrog caramel xim, phenolic xim, Maillard xim thiab lwm yam. Txij li cov kua khib nyiab muaj txog 10% cov khib nyiab, cov concentration tsawg thiab siv tsis tau. Yog hais tias nws raug tso ncaj qha mus rau hauv cov dej ntws thiab ua liaj ua teb yam tsis muaj kev kho mob, nws yuav ua rau cov dej tsis zoo thiab ib puag ncig, lossis ua rau cov av acidification thiab compaction, thiab kev loj hlob ntawm cov kab mob qoob loo. Yuav ua li cas nrog thiab siv cov kua txiv molasses cawv pov tseg yog ib qho teeb meem loj ntawm kev lag luam qab zib.

Molasses cawv khib nyiab kua yog corrosive heev thiab muaj chroma siab, uas yog ib qho nyuaj rau tshem tawm los ntawm txoj kev biochemical. Concentrated incineration lossis high-efficiency kua chiv yog cov kev npaj kho mob zoo tshaj plaws tam sim no.

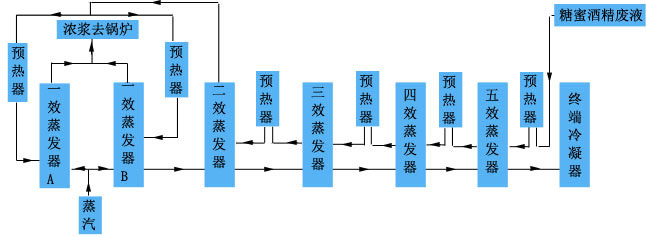

Cov cuab yeej siv lub tshuab hluav taws xob tsib-txhim kho cov txheej txheem ua haujlwm-down evaporation system, nrog rau cov chav dej saturated raws li qhov chaw tshav kub, ib qho hluav taws xob cua sov thiab tsib-txheej xwm ua haujlwm. Cov kua txiv hmab txiv ntoo cawv pov tseg nrog cov concentration ntawm 5 mus rau 6% yog concentrated thiab evaporated, thiab ib tug concentrated slurry muaj ib tug concentration ntawm ≥ 60% yog xa mus rau lub boiler rau incineration, thiab cov generated tshav kub heev txaus siab rau lub chav rau lub ntaus ntawv. Evaporate cov dej condensed rov qab mus rau ntu dhau los rau cov dej dilution.

Thib ob, cov txheej txheem khiav daim ntawv qhia

Thib peb, cov yam ntxwv ntawm cov txheej txheem

1. Teem lub evaporator seem kom tshem tawm cov khoom, uas tuaj yeem paub txog kev tu tsis tu ncua thiab xyuas kom muaj kev tsim khoom tas mus li.

2. Lub cuab yeej txais kev tswj hwm kev tswj hwm tsis siv neeg kom txuag tau tus nqi zog.

3. Kev ua haujlwm siab thiab kev ua haujlwm ruaj khov.

4. Los ntawm kev siv cov slurry tuab kom rov qab mus rau lub boiler, molasses tuaj yeem tsim cawv tsis ntxiv roj.

5. Lub evaporator spare yog teem rau cov nyhuv tawm, uas tuaj yeem paub txog kev tu tsis tu ncua thiab xyuas kom muaj kev tsim khoom tas mus li.

6. Cawv tuaj yeem tsim los ntawm cov kua nplaum uas tsis ntxiv roj los ntawm cov slurry tuab rau lub boiler rau rov siv dua thiab cov kua nplaum.